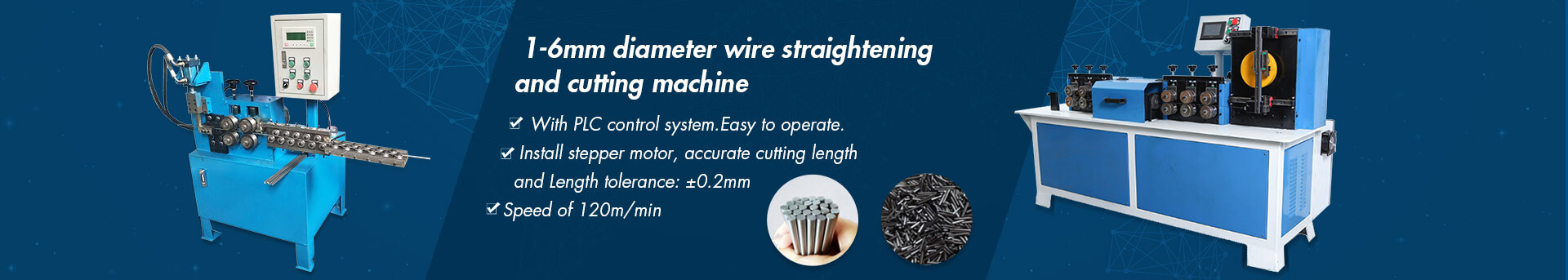

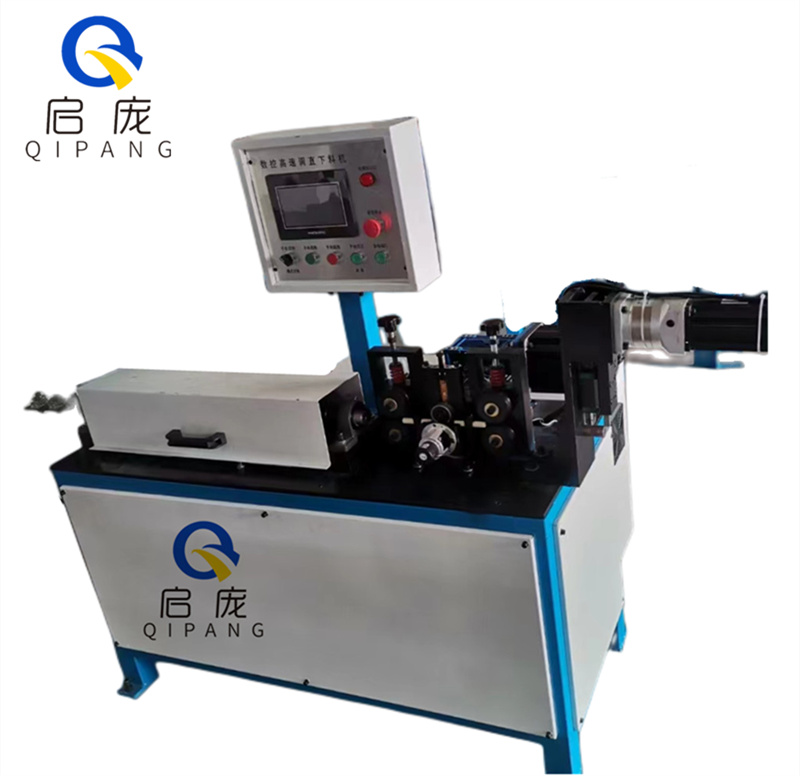

QIPANG High-Quality Cable Straightening Cutting Machine

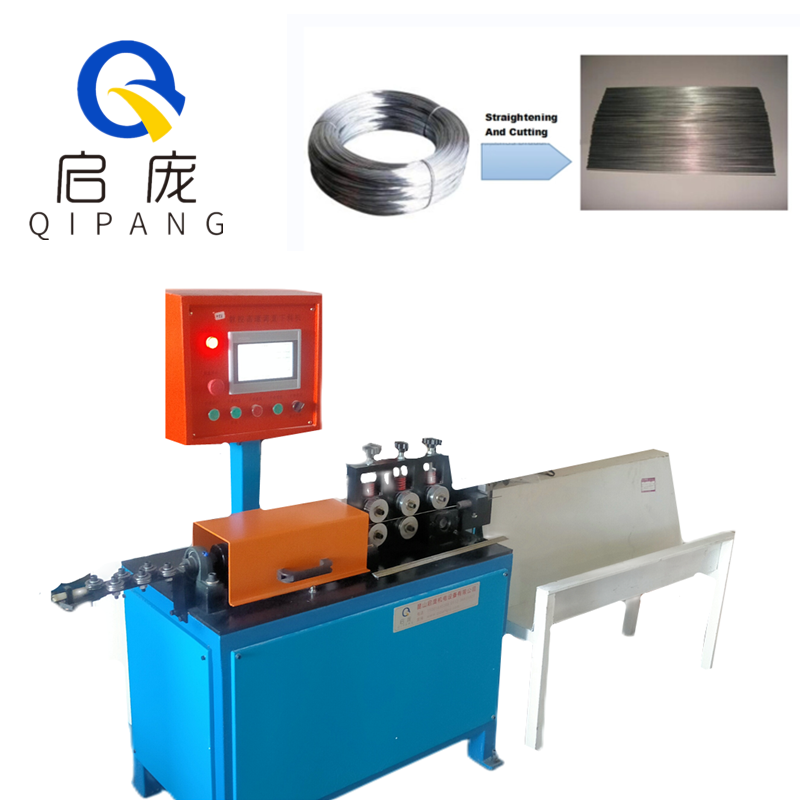

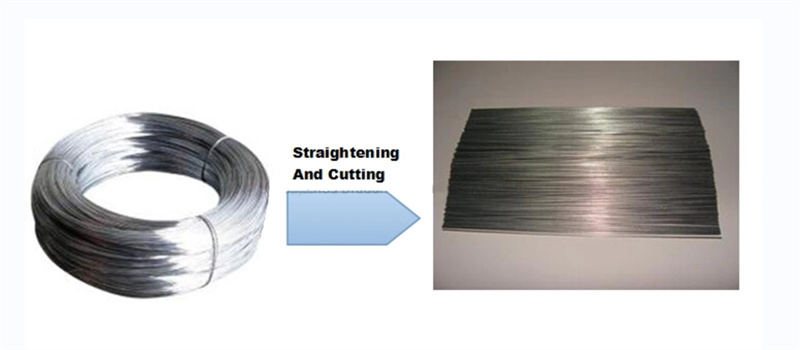

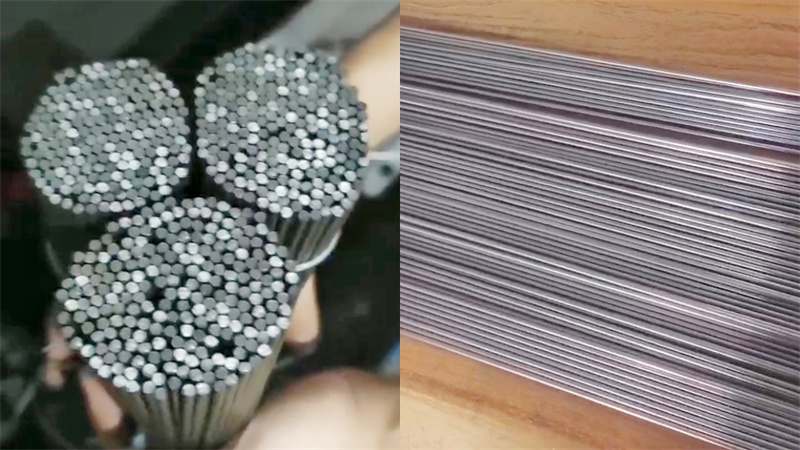

This Cable Straightening Cutting Machine can be suitable for all kinds of metal wire straightening cutting, surface, no scratches, cutting length error of 0.2-0.5 mm, and the cutting length range is 80mm to 6000mm. Human-machine incorporate touch screen control system can save manpower for the customer. The company's main range of wire 1 mm to 5 mm can be customized, fastest of up to 150 meters per minute, available for copper, iron, aluminum, gold, silver, stainless steel, high carbon steel and plastic coated wire, metal wire. If you want faster speed for cable straightening cutting machine, please contact customer service. If you are concerned about the straightening effect, we can provide free proofing.

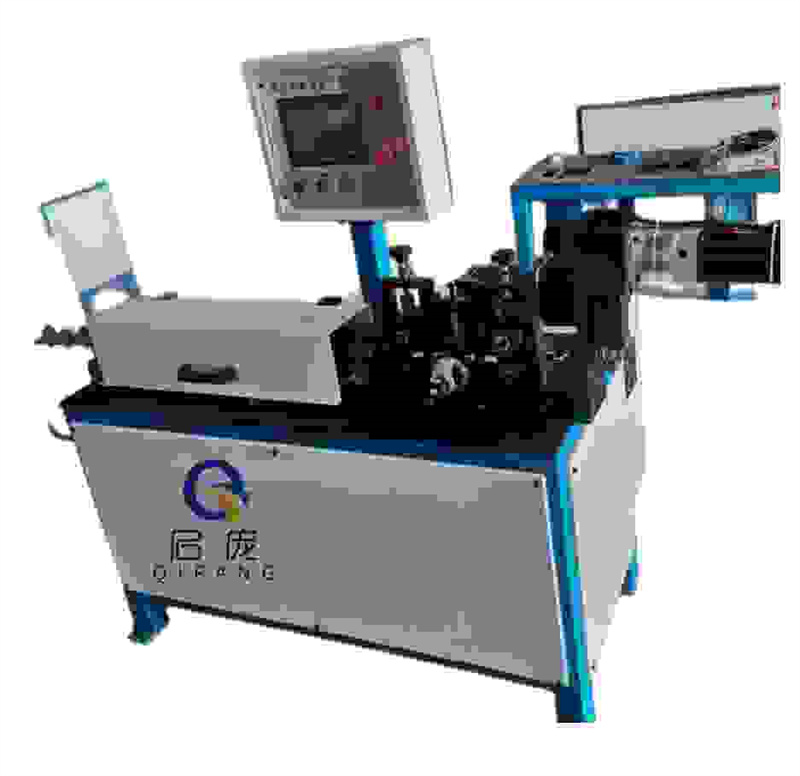

Configuration parameters of Cable Straightening Cutting Machine

1 two servo motors, 1.5 kw traction and 1:10 planetary reducer, cut off 1.5 kw,

2 cut off the PLC touch screen electronic CAM system,

3 servo motor brand, servo motor

4 fuselage length 1850mm wide 780mm total height 1300mm.It weighs about 498 kilograms.

5 the total weight of the automatic spreader is 90kg.

6 The control mode includes inverter analog control system,

7 Minimum diameter: 250mm; maximum diameter: 500mm;

8 the weight of the spreader is about 90kg"

Application of Cable Straightening Cutting Machine

Cable manufacturing: Cable Straightening Cutting Machines are commonly used in cable manufacturing to straighten and cut wires and cables to the desired length. They are used to make power cables, control cables, and other types of cables used in electrical and electronic applications.

Wire processing: These machines are also used in wire processing industries to straighten and cut wires used in construction, automotive, and other industries. They can straighten and cut wires made of copper, aluminum, and other metals.

Scrap recycling: Cable Straightening Cutting Machines can also be used in scrap recycling operations to straighten and cut scrap wires and cables for recycling.

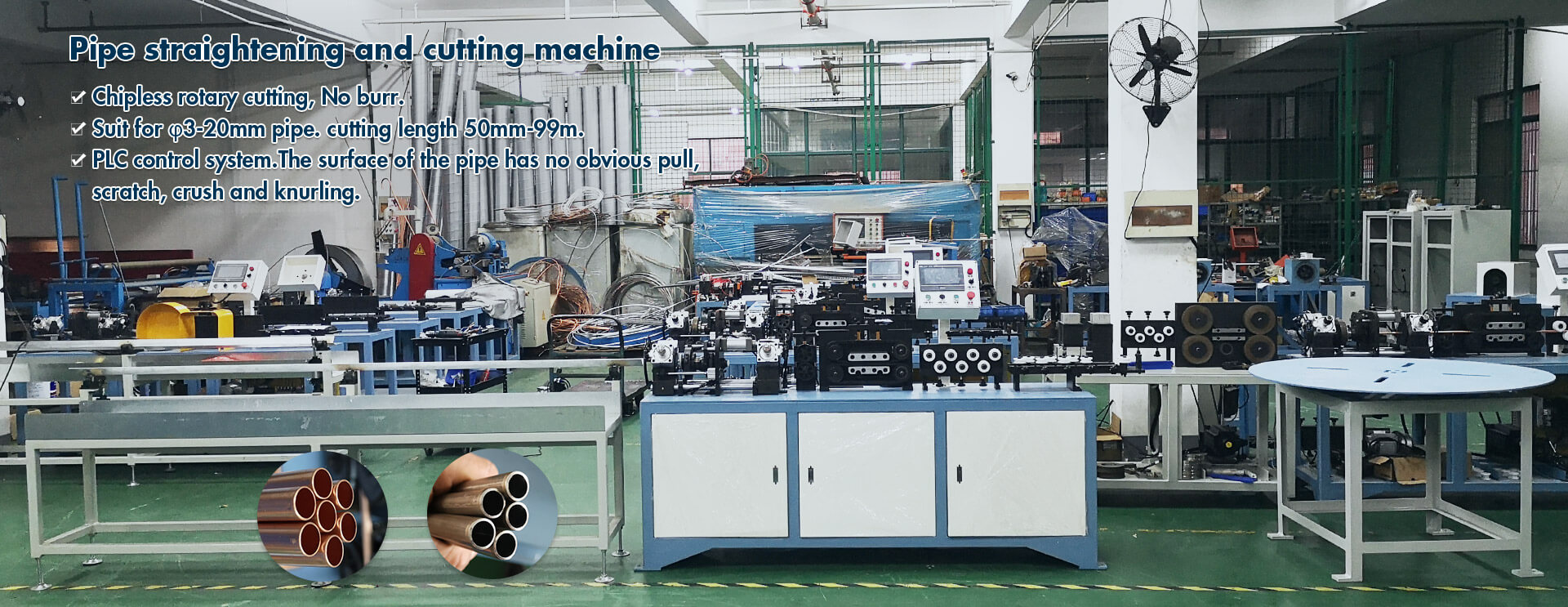

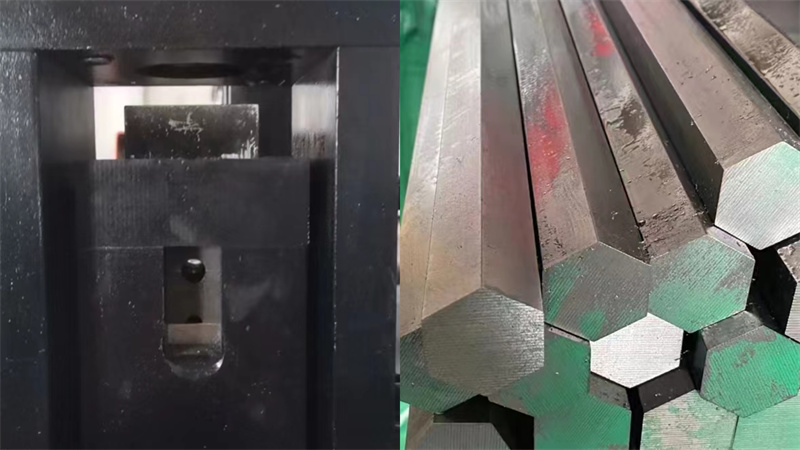

Metal fabrication: They are also used in metal fabrication workshops to straighten and cut metal rods, pipes, and other metal parts that may have been bent or twisted during the manufacturing process.

Maintenance and repair: These machines can also be used in maintenance and repair operations to straighten and cut metal parts that have been damaged or bent during use.

Cable Straightening Cutting Machine Packing: