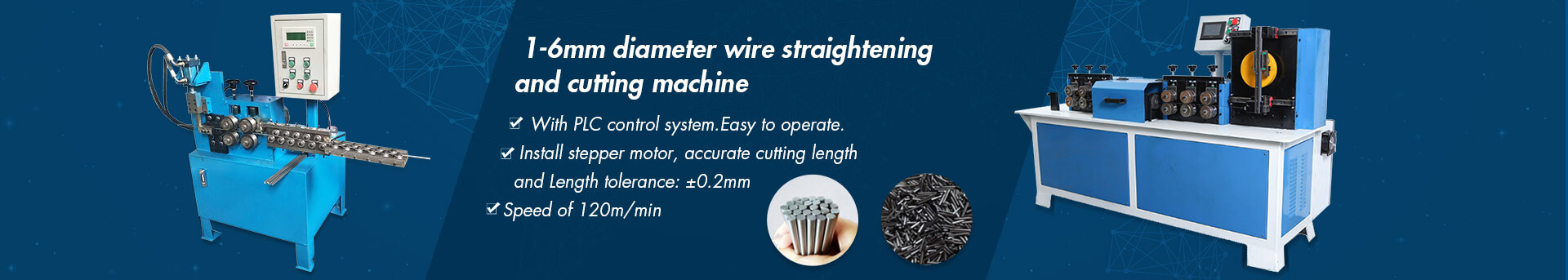

Galvanized wire straightener, electrical wire straightenerand cutter with wire guides and straightening rollers

Besides, we are willing to offer customed service.

Specifications

1. Model:2700x1500x800mm

2. Drilling crew plane height: About 850mm

3. Weight:500kg

4. Power Supply: Three-phase five-wire 380v bring zero line and ground wire

5. Power: 3kw

6. Air Pressure: 0.5-0.8mpa

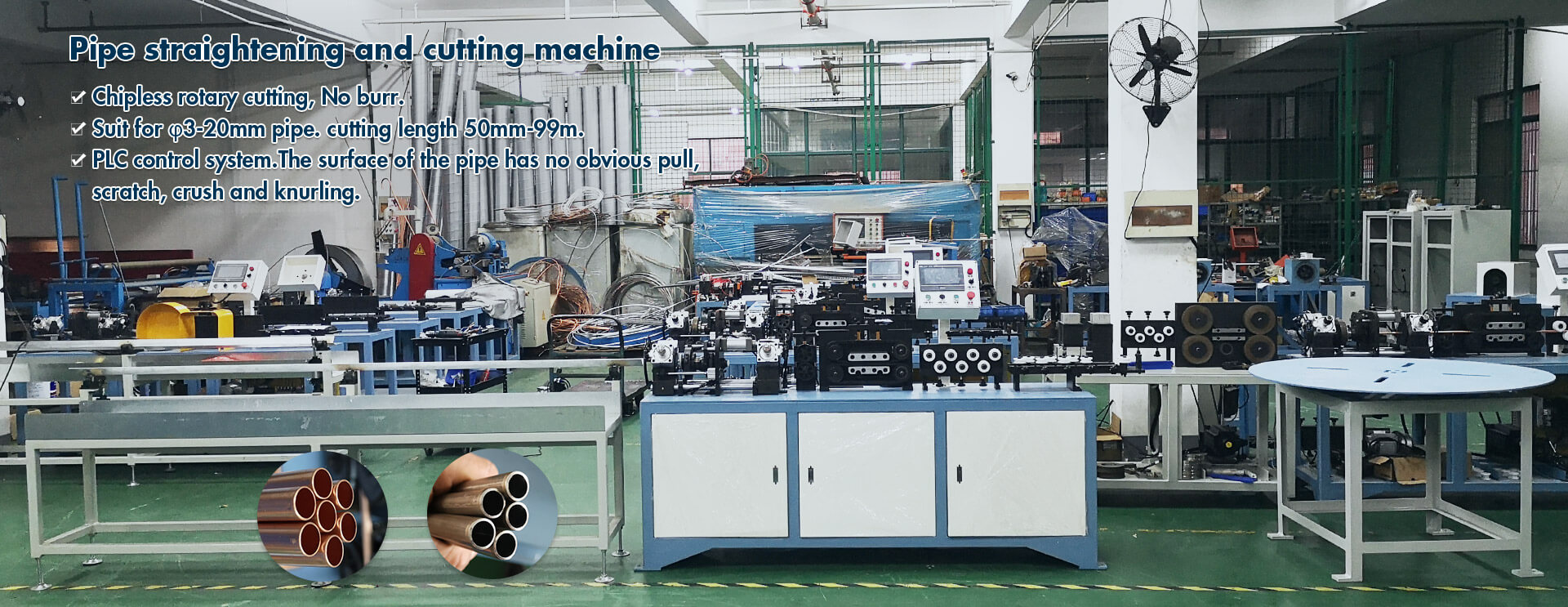

7. rough shape cutting to adapt to the pipe:4-16 aluminium tube;4-16 copper pipe;4-16 band pipe

8. Feeding speed: 0-50M

9. cutting ways: Single - knife direct rotation without cuttings cutting. clipping time: 2-2.5S/time. Three meters per time about 6 seconds, An eight-hour day produces about 3,000 to 4,000 pieces.

10. Equipment use field: Automobile, air conditioning, refrigerator freezer, water dispenser, home appliance, etc.

11. control principle:PLC programmable logic controller,OP-320text operation,Synchronous belt feeding,servo motor drive,Japan omron rotary encoder counting,The pneumatic original adopts SNS.

12. This machine is aimed at the following (copper tube). The tube is straightened to the straightening mechanism of the main engine, and the servo motor drives the synchronous belt to drive the pipe to the cutting-free cutting machine.Finally, it is taken over by pneumatic aggregates, and the whole process is automatic and reliable. The machine break up and operate automatically, the mold change is simple, the operation is simple, the production efficiency is high.

13. Main structure and principle:Mechanical structure: it is composed of flat rack, straightening group, feeding tube section, cutting head section and feeding frame.

Gas path control: cylinder clamp, servo drive synchronous belt feeding tube, cylinder clamp, cutting tube, pull, cylinder connection.

Circuit control system: by PLC control servo motor forward tube, after the length of the encoder, after reaching the set length, the PLC control solenoid valve action, drive the cylinder to cut off the pipe.

Processing pipe: this equipment is a single pipe equipment, and the size of the open material pipe is applicable to the mechanical limit range. Different materials need to be replaced with straightening wheel, feeding belt, mould and central pipe.

14. Machine Features:

The precision is special, can be according to the customer's product process request and according to the purchase cost budget to make the material way, the tube is cut neatly, the rate is small or no burr, no cuttings to cut any choice.

Is simple and convenient operation, automatic control and manual control two ways, the operator easy-to-learn, smooth feeding, high degree of automation, no material and reach a preset number of cutting, automatic stop.

It is easy to maintain and maintain, use pneumatic components to control and implement parts, less lubrication points, no pollution, quick and convenient replacement of parts, and easy to keep the equipment clean.

Quick installation coil, feeding frame can use double-sided active feeding plate, can prevent materials plate caused by inertia feeding is too long, or caused by the pipe is too thin and pipe strain, so as to ensure the quality of copper pipe cutting. It can also be used for flat loading rack and easy to install copper pipe.

Recommended Products

About us

With more than 10 years of experience:

QIPANG has established an excellent reputation in the industry through the highest quality products designed and manufactured by outstanding engineering teams and providing our customers. After more than 10 years of continuous supply and maintenance of the highest quality machinery, tools, and accessories to the wire straightening industry, this excellent word of mouth continues today.

Committed to customer satisfaction:

QIPANG is known worldwide for developing and selling a wide range of straightening tools and accessories. We consistently use the highest quality materials and equipment to build our products, which has always been our corporate philosophy.

Here, we are committed to making quality and service satisfaction to our customers around the world. Whether our customers need standard products or custom-made products, QIPANG has the following qualities:

1. 10 years of development,manufacturing, market experience

2. A wide range of tool components

3. highest quality requirements and guarantees

4. Flexible development and customization tools

5. Excellent consulting team covering the world

6. Fast spare parts distribution and sufficient inventory

7. Guaranteed risk-free warranty management

8. Solutions, from the very beginning.

In addition, QIPANG is located at Zhaofeng Road Subway Station, No. 11 Jiading Anting, Shanghai.

Since 2009, the metal products series machine has been provided.

Q1: Are you a factory or trading company?

We are a factory . We can promise you a short lead time and best price if you purchase our machine. We also have our own trading department.

Q2: How does the factory ensure products quality?

With Nearly 16 years experience in manufacturing winding machine, we have our own technology develop department and testing department.

Quality is the first priority. We have strict purchasing system to ensure the quality of spare parts. We have experienced workers to assemble and test machine.

Q3:How about your after-sale service?

We have a professional technology supporting team for your timely services. You can get the help you need in time by telephone, webcam, online chat (Google talk, Facebook, Skype). Please contact us once the machine has any problem. Best service will be offered.

Q4: What are your payment terms?

100%TT or prepaid 50% , balance 50% before shipping.

Q5: How can I get my order? How can I know you sent the goods?

We will send the goods by UPS, DHL, FedEx or sea shipment. After we sent the goods, we will give you the tracking number or other relative files for checking.

Q6 : Will you send the installed machine or machine parts?

We will install the machine and test the machine before delivery. And the machine can be used directly after receiving the machine.

Q7: Will you provide operation guidance for us?

We will send the instruction book with the machine and send you a video about how to operate the machine.

Q8 : How long is the warranty period?

12 months warranty, we will send you free spare parts by air within one week if there are any quality problems.

Q9 : What certification do you have?

All of our machines have the SGS certification which ensures the quality and safety. Our machines are under strict quality management to ensure good quality. Because we fully understand that it will be a great trouble if machine have any problem during working at oversea. We are an ISO9001:2008 quality management system certificated manufacturer.