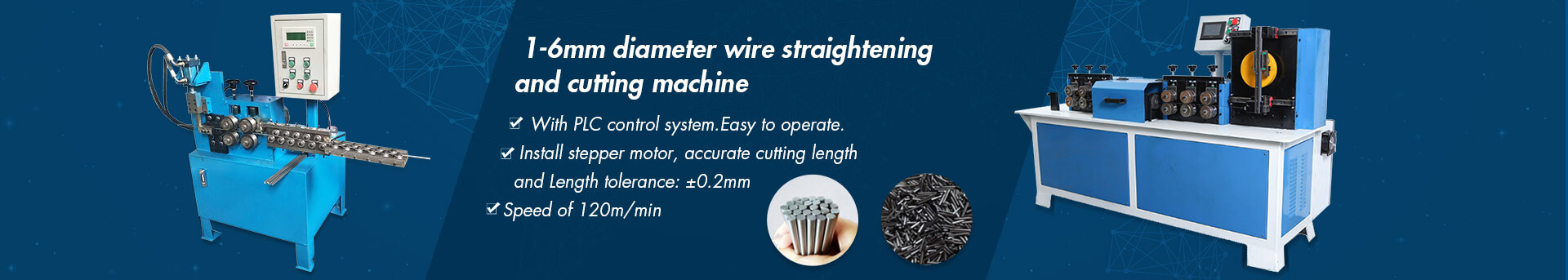

QIPANG QR0.3-0.5/AV model wire straightening machine for 0.3-0.5 mm steel wire straightener tool

Mainly used on drawing machines

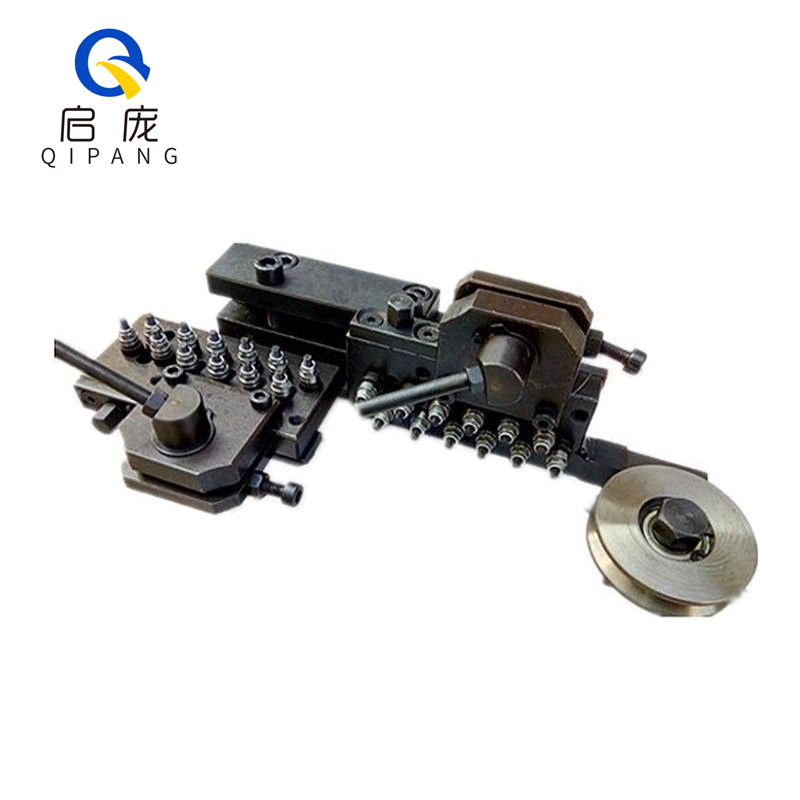

1,Single and dual plane straightener models JZQ 0.2-0.5/34 AV JZQ 0.2-0.5/18 AV

2,Eccentric roller open/closing device (lever)

3,Quantity of roller in stock 17+17 ,From 5 ~ 19 rollers per group (5+5,7+7,9+9,11+11,13+13,15+15,17+17,19+19)

4,Roller diameters 12 mm (0.4724"), Customizable 7-120mm (0.4724"--4.7244" )

5,Adjustable rollers on the upper row

6,Rollers available for light or heavy-duty applications

7,Model AS/AD for wire R = 60 N/mm2 (8400 psi) max. with normal rollers (single or double bearing)

8,Rollers are standard "V" groove profiles but can be provided with "U" grooves 9, according to customer requirements

*Wire Guide included

Wire Straightening Tool Advantages:

1. CE&SGS certification,ISO1990 Quality system certification

2. Fast spare parts distribution and sufficient inventory

3. 10 years of development, manufacturing, and market experience

4. Flexible development and customization tools

5. Excellent consulting team covering the world

6. Flexible development and customization OEM/ODM

Wire Straightening Tool Technical Parameter

| Model | Type | Wire Diameter (Solid) | Roller Diameter (mm/inch) | Roller Qty (pcs) | structure | groove |

| JZQ 0.05-0.2/38AV | V-7 | φ0.05-0.2mm | 7(0.276) | 38 | quick clamping | V |

| JZQ 0.2-0.5/34AV | V-12 | φ0.2-0.5mm | 12(0.472) | 34 | V | |

| JZQ 0.5-0.8/26AV | V-16 | φ0.5-0.8mm | 16(0.630) | 26 | V | |

| JZQ 0.8-1.5/5/18AV | V-23 | φ0.8-1.5mm | 23(0.906) | 5/18 | V | |

| JZQ 1.5-3/5/18AV | V-30 | φ1.5-3mm | 30(1.181) | 5/18 | V | |

| JZQ 3-4/18AV | V-32 | φ3-4mm | 32(1.260) | 18 | V | |

| JZQ 4-7/14/18/22AV | V-42 | φ4-7mm | 42(1.654) | 14/18/22 | unclamping | V |

| JZQ 5-8/14/18/22AV | V-54 | φ5-8mm | 54(2.126) | 14/18/22 | V | |

| Model | Type | Tube/Pipe Diameter (Hollow) | Roller Diameter (mm) | Roller Qty (pcs) | structure | groove |

| JZQ 1-3/14/18 BU/R | U-30 | 1-3mm | 30 | 18/14 | quick clamping | U/R |

| JZQ 4-10/14/18/22 BU/R | U-42 | 4-10mm | 42 | 14/18/22 | unclamping | U/R |

| JZQ 10-20/14/18/22 BU/R | U-54 | 10-20mm | 54 | 14/18/22 | unclamping | U/R |

| I. Different groove types can be customized. II. Quick clamping is a straightener with a handle for easy opening and closing of the rollers | ||||||

Introducing the QIPANG QR0.3-0.5/AV model wire straightening machine, an exceptional wire straightening tool designed specifically for 0.3-0.5 mm steel wires. As a leading manual iron wire straightening machine manufacturer, we take pride in delivering high-quality products from our state-of-the-art factory.

The QIPANG QR0.3-0.5/AV model wire straightening machine offers exceptional efficiency and precision, allowing you to straighten steel wires with ease. With its user-friendly design and easy operation, this wire straightening tool simplifies your wire straightening processes, saving you time and effort.

The QIPANG QR0.3-0.5/AV model wire straightening machine is designed for easy use, making it suitable for both beginners and experienced professionals. It's intuitive controls and adjustable settings allow for precise wire straightening, providing excellent results regardless of your skill level.

Experience the convenience and efficiency of our easy use steel wire straighteners. Whether you are in the manufacturing, construction, or electrical industry, our wire straightening tool is a reliable and essential asset for your operations.

Choose QIPANG as your trusted wire straightening machine manufacturer, and unlock the full potential of your wire straightening processes. With our commitment to quality and customer satisfaction, we ensure that each product from our factory meets the highest standards.

Upgrade your wire straightening operations with the QIPANG QR0.3-0.5/AV model wire straightening machine. Contact us today to learn more about this high-efficiency wire straightener and how it can enhance your productivity and streamline your wire processing tasks.

The Finished Product to Show

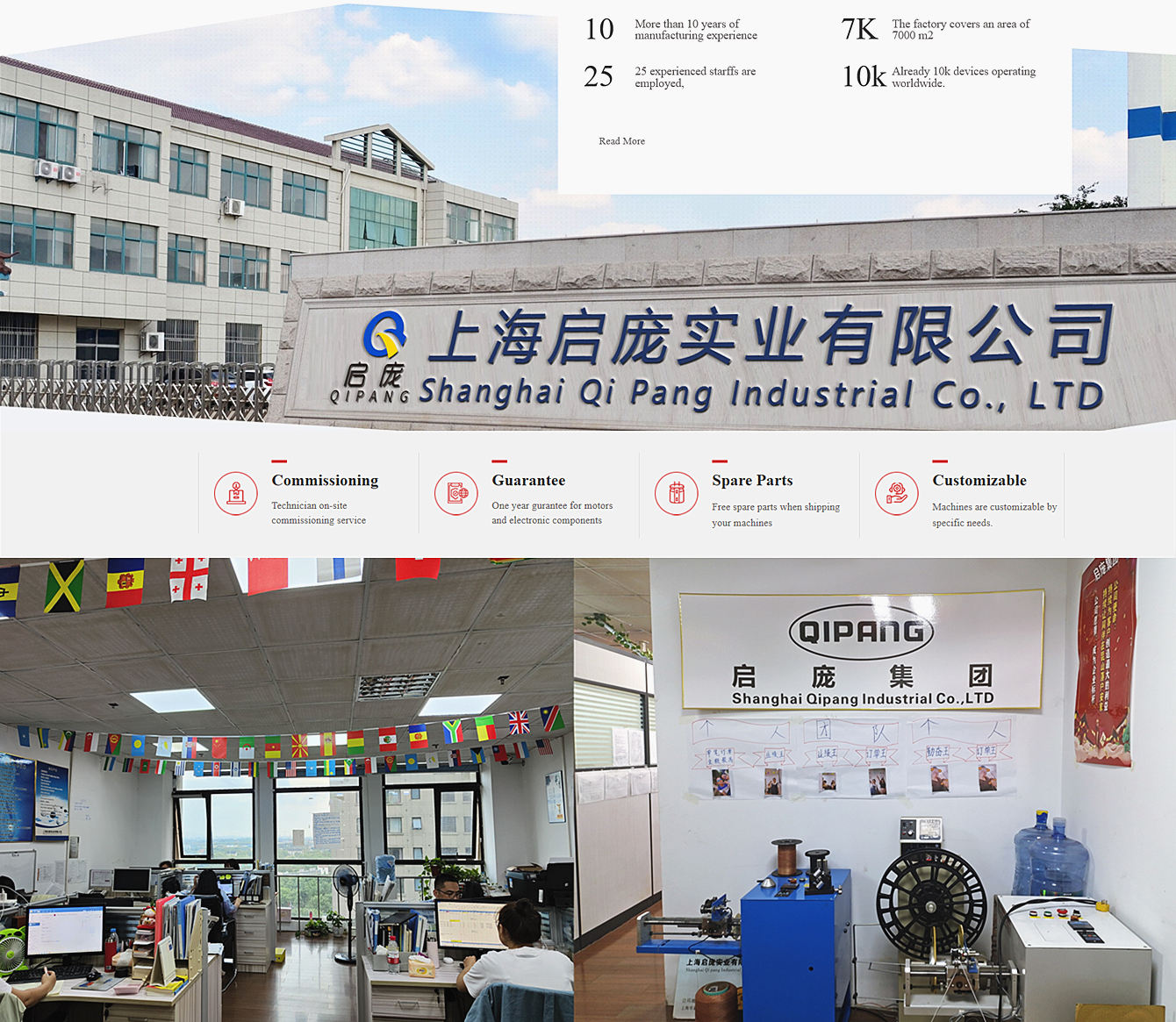

Why Choose Qipang?

After-Sales Service

1. Maintenance period: one year

2. Training how to install the machine, training how to use the machine.

3. Engineers available to service machinery overseas.

4. Test the machine before shipment

5. Provide technical guidance related to the use of the machine

6. Provide the spare parts at cost price after the warranty period

7. Collect the feedback for the machine working

Purchase Confirmation

Pls tell me the following questions, so we can send you an accurate quotation with an additional discount:

1, What's the diameter of your steel wire? Minimum and maximum range, How to choose the right straightener according to their own material?

2, Does the raw material come in rolls, in bundles, Hollow rolls or solid material?

3, Have you used it before? Now do you have any pictures you want to send to us?

4, If you are interested in our products, please contact me as soon as possible, I will offer you some discounts.