belt feeder

01

Product introduction

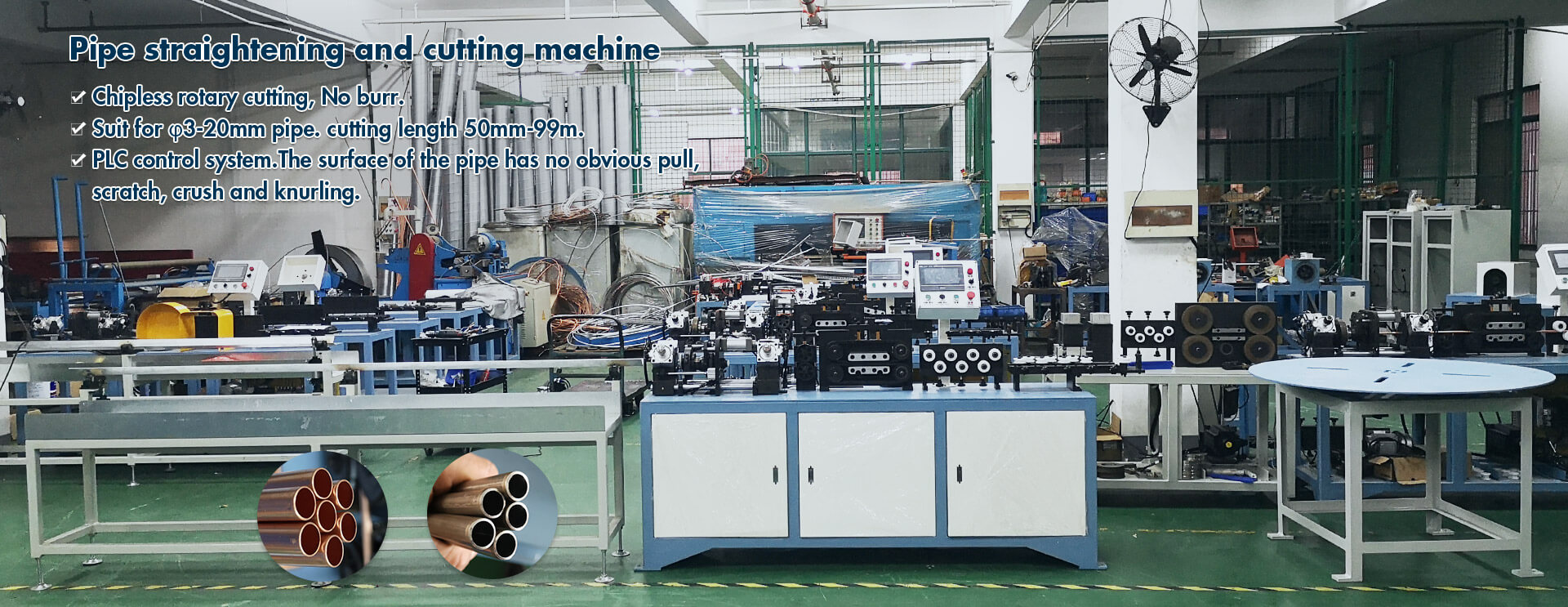

belt feeder suit for pipe matrail, such as copper pipe, aluminium pipe

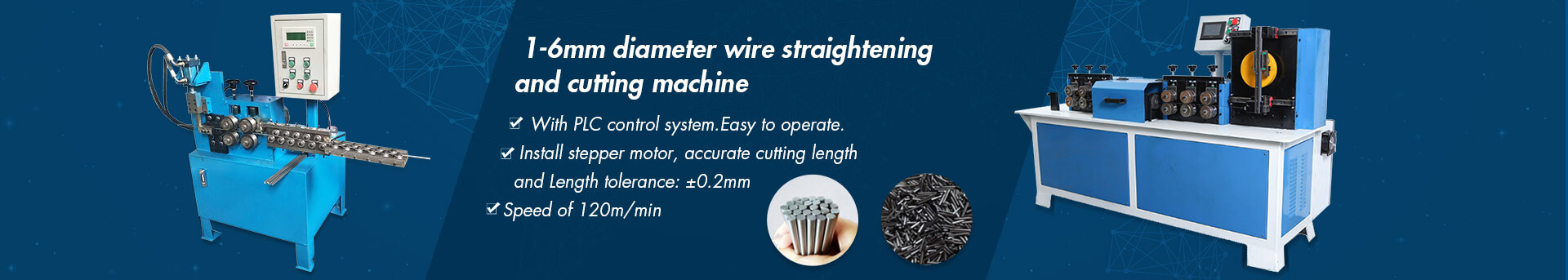

belt feeder suit for wire material such as the steel wire, copper wire

belt feeder Ability to handle material diameters 0.5mm to 30mm

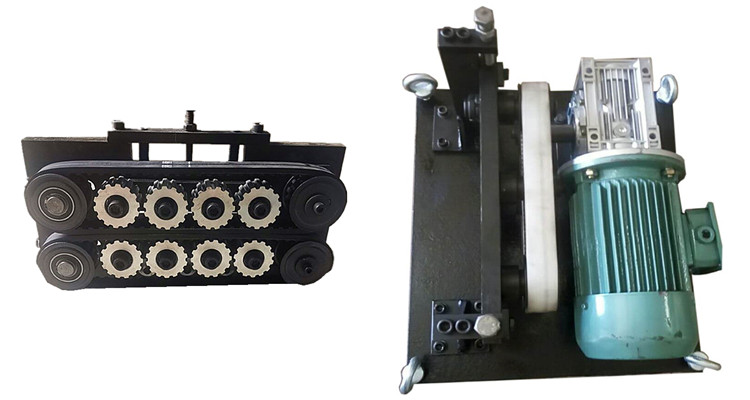

Toothed belt dual driven rolls or chain drive rolls

belt feeder Various number of rolls, clamping methods, and drive styles for a specific pulling force

Hydraulic, pneumatic, or manual adjustment

Custom built machines that can include feeders and straighteners

The transported material is installed in the bearing member connected with the traction part, or directly installed in the traction part (such as conveyor belt), traction parts around the drum or sprocket end to end connected, forming a closed loop containing the load branch and no load branch of the transport of materials, the continuous activity of the application of traction parts conveying materials.

02

Profile Display

03

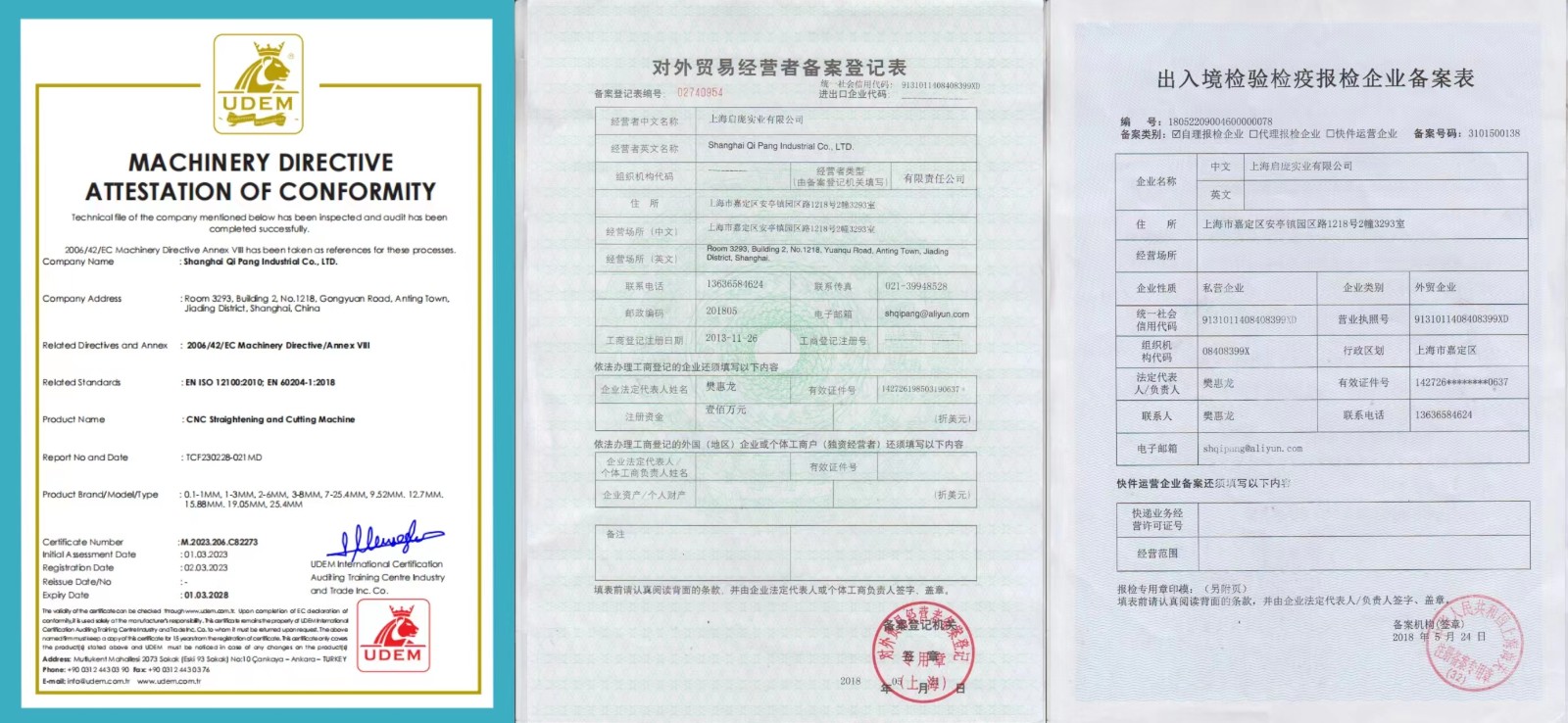

Certificate

belt wire feeder

Ultimately, our suggestion for the best straightener for your processing requirements will depend upon the material you are processing. So please, do not hesitate to call +86 150 0283 0288 or contact us here for help.belt wire feeder

For purchasing ease, we supply a variety of wire straightener accessories for ease of set-up and “repeatability” of settings. For example: quick opening/closing options, roller position indicators, locking levers, entry/exit guide pulleys, guide dies, micrometer adjustment, guards.belt wire feeder

In addition, our wide range of raw material handling products includes: tube straighteners, wire guides and tube guides, tube feeders and wire feeders or drive units, cable straighteners, strip and flat wire straighteners, custom built feeding machines, straightening rolls, preform heads, sleeve rolls for high speed and high temperature applications, computerized wire straightener and tube straightener adjustment systems.belt wire feeder

Wire Straighteners,Straightening Machines-Qipang customized solutions (wire-straightener.com)