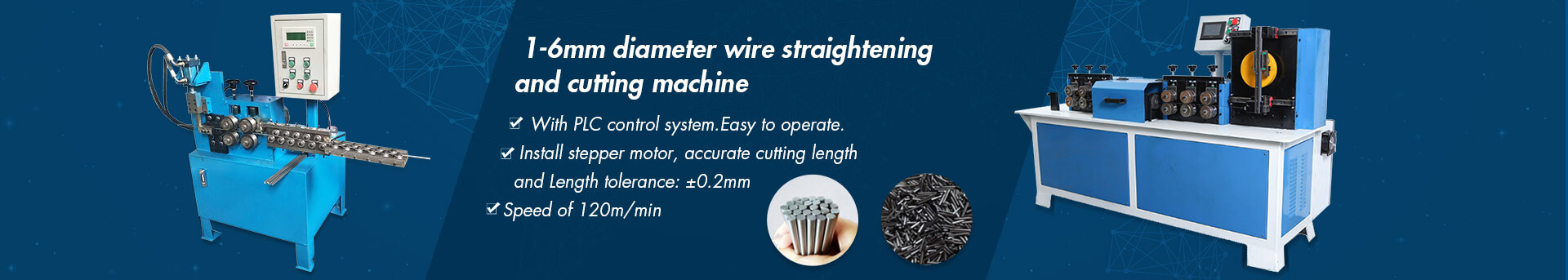

Qipang new type 14 Rollers Wire Straightening Machine steel wire straightened wire straightening tool

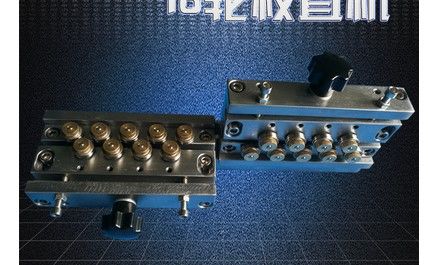

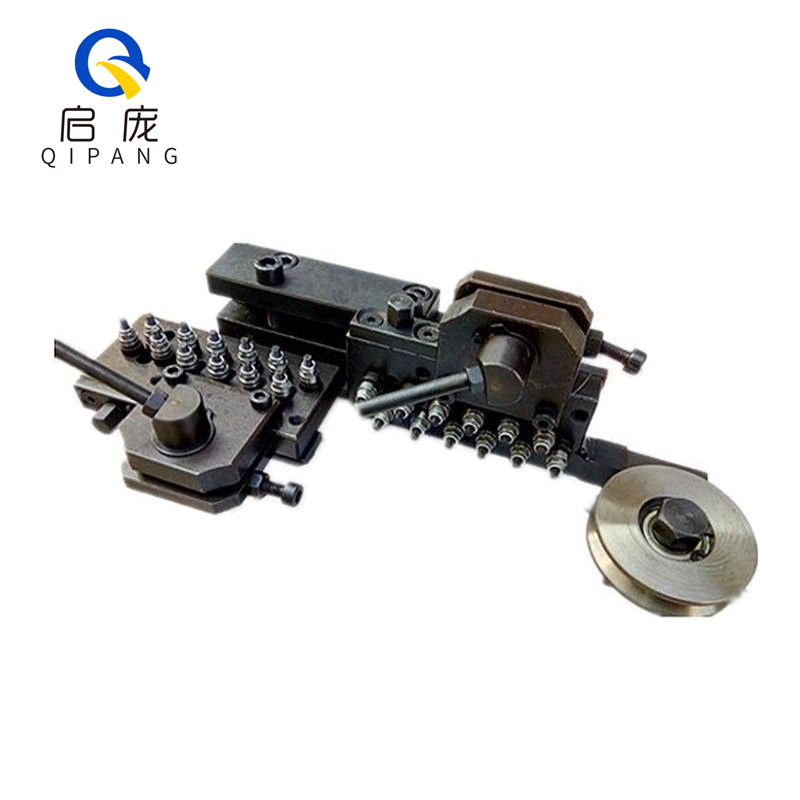

A 14 rollers wire straightening machine is a type of machinery used in the manufacturing process of straightening wire. It typically features 14 rollers that are used to straighten and smooth out wire as it passes through the machine. The rollers are usually made of hardened steel and are arranged in a specific configuration to ensure that the wire is straightened evenly and to the desired specifications. This type of machine is commonly used in construction, engineering, and other industries that use wire as a raw material.

Mainly used on drawing machines

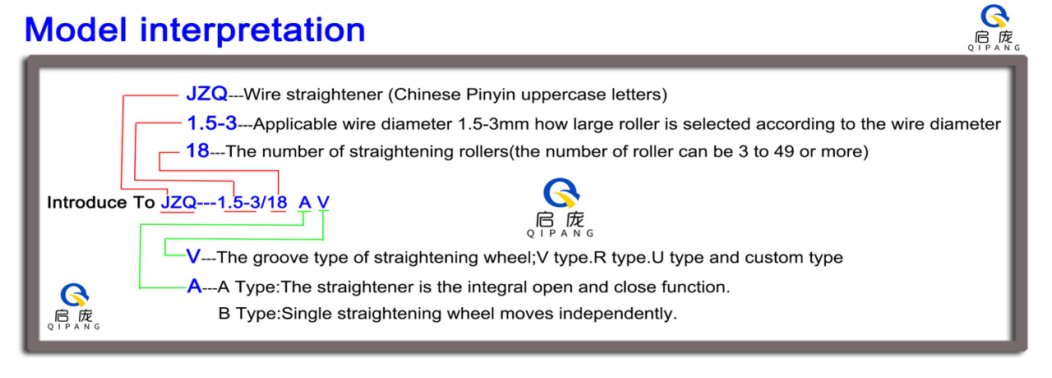

1, Single and dual plane straightener models JZQ 4-7/14/14AV

2, Eccentric roller open/closing device (lever)

3,Quantity of roller in stock 7+7 ,From 5 ~ 19 rollers per group (5+5,7+7,9+9,11+11,13+13,15+15,17+17,19+19)

4,Roller diameters 37mm (1.457") ,,Customizable 23-120mm (0.905"-4.724409")

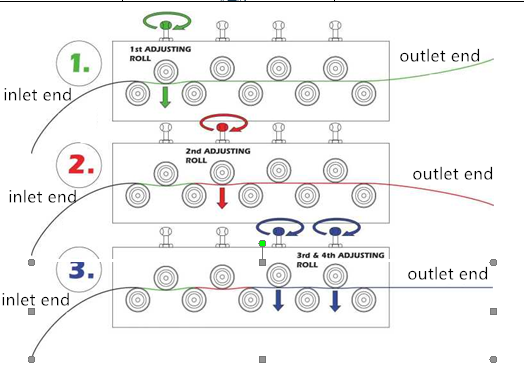

5,Adjustable rollers on the upper row

6, Rollers available for light or heavy duty applications

7,Model AS/AD for wire R = 60 N/mm2 (8400 psi) max. with normal rollers (single or double bearing)

8,Rollers are standard "V" groove profiles but can be provided with "U" grooves 9,according to customer requirements

*Wire Guide included

14 Rollers Wire Straightening Machine Advantages:

1, straightener roller material surface without scratches. It is made of bearing steel and nylon.

2, straightening wheels are made of bearings, using alloy roller group, carbide wheels, can be configured according to product specifications and customer requirements.You can do v-groove, U-groove, h-groove.

3, straightener straightness theoretically: the more the number of roller wheels, the better the straightening effect, the more variations,

4, straightener adjustment structure: with handle structure, can be opened and closed as a whole, save time.

14 Rollers Wire Straightening Machine Detailed parameters

| Model | Type | Wire Diameter (Solid) | Roller Diameter (mm/inch) | Roller Qty (pcs) | structure | groove |

| JZQ 0.05-0.2/38AV | V-7 | φ0.05-0.2mm | 7(0.276) | 38 | quick clamping | V |

| JZQ 0.2-0.5/34AV | V-12 | φ0.2-0.5mm | 12(0.472) | 34 | V | |

| JZQ 0.5-0.8/26AV | V-16 | φ0.5-0.8mm | 16(0.630) | 26 | V | |

| JZQ 0.8-1.5/5/18AV | V-23 | φ0.8-1.5mm | 23(0.906) | 5/18 | V | |

| JZQ 1.5-3/5/18AV | V-30 | φ1.5-3mm | 30(1.181) | 5/18 | V | |

| JZQ 3-4/18AV | V-32 | φ3-4mm | 32(1.260) | 18 | V | |

| JZQ 4-7/14/18/22AV | V-42 | φ4-7mm | 42(1.654) | 14/18/22 | unclamping | V |

| JZQ 5-8/14/18/22AV | V-54 | φ5-8mm | 54(2.126) | 14/18/22 | V | |

| Model | Type | Tube/Pipe Diameter (Hollow) | Roller Diameter (mm) | Roller Qty (pcs) | structure | groove |

| JZQ 1-3/14/18 BU/R | U-30 | 1-3mm | 30 | 18/14 | quick clamping | U/R |

| JZQ 4-10/14/18/22 BU/R | U-42 | 4-10mm | 42 | 14/18/22 | unclamping | U/R |

| JZQ 10-20/14/18/22 BU/R | U-54 | 10-20mm | 54 | 14/18/22 | unclamping | U/R |

| I. Different groove types can be customized. II. Quick clamping is straightener with a handle for easy opening and closing the rollers | ||||||

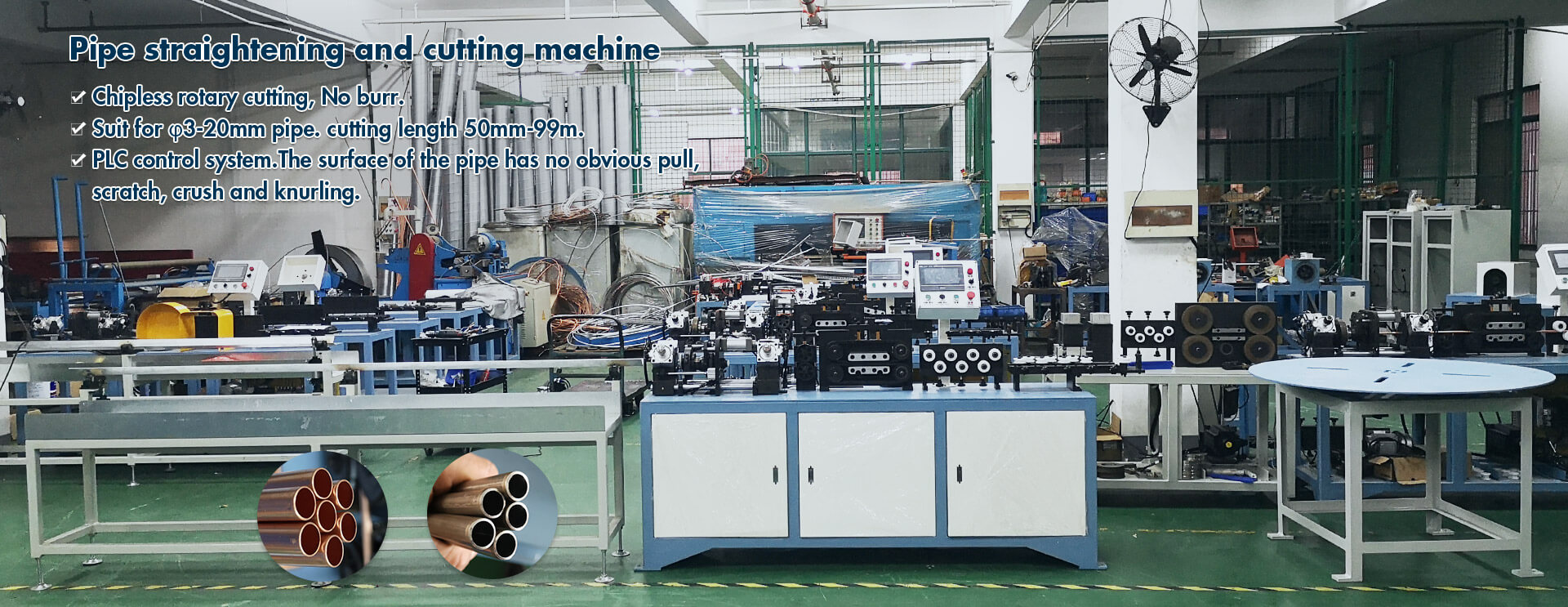

Qipang Straightener series

Qipang Factory & Store

Who are we?

Shanghai Qibang Industrial Co., Ltd.Founded in 2000, with 13 years of experience, is a research and development, production, sales of wire straightening cutting machine, wire forming bending machine, molding machine, copper pipe cutting machine equipment as one of the large machinery manufacturing enterprises.

We believe that quality is survival, so we only provide you the best products.

High quality products, in line with international standards, well received by domestic and foreign customers.

All staff in our company are professionally trained, so we can recommend the most suitable equipment for you.

Every machine has to pass strict inspection before it goes out.

Any questions about the machine will be answered within 24 hours.

Welcome to be our new customer!

Shanghai Qi Pang Industrial Co., LTD. specializes in producing wire straightening machine and rebar and tube cutting machine with advanced production technology, modern production mode, complete varieties and diverse styles. We can provide you with not only the nice quality products but also the great services.

14 Rollers Wire Straightening Machine Package and transport

1.Maintenance period: one year

2.Training how to install the machine, training how to use the machine.

3.Engineers available to service machinery overseas.

4.Test the machine before shipment

5.Provide technical guidance relate to use the machine

6.Provide the spare parts at cost price after warranty period

7. Collect the feedback for the machine working

Pls tell me the following questions, so we can send you accurate quotation with additional discount:

1,What's the diameter of your steel wire ? Minimum and maximum range,How to choose the right straightener according to their own material?

2,Does the raw material come in rolls, in bundles, Hollow roll or solid material?

3,Have you used it before? Now do you have any pictures you want to send to us?

4,If you are interested in our products, please contact me as soon as possible, I will offer you some discounts, you can contact me freely:Whatsapp:+8613472630866/ Wechat:+8618916332415

FAQ about 14 Rollers Wire Straightening Machine:

Q: Are you a manufacturer?

A: Yes, we are manufacturer of nail making machine.Welcome to visit us!

Q: what's the MNQ, Can you offer the customer service?

A: The MNQ is 1 set, we provide customized service, as long as you provide drawings

Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details!

Q: What should I do to start a new business in nail making machine area?

A: Please contact us immediately, we provide free pre-sales consultant service of nail making machine.

Q: Why choose you? What is the difference between you and other Chinese supplier?

A:We have specialized in this area for over 13 years.Our nail making machine are exported to Russia,India,UAE,South Korea,Canada,Vietnam,Thailand,Mexico,Turkey and etc. You can get higher quality product & better professional service from Hitech with same price.

Q: I'm worried about after-sales service!

A: Warranty is one year.

Any parts damaged during the warranty will be replaced for free!

We provide spare parts for a lifetime at a cost price.

Electrical parts such as boards and servo drives, we'll provide them for life time as well at cost price.

Our engineers are available to service overseas!