The six-roll straightener is a commonly used machine for straightening wires, bars, and tubes. By adjusting the position and gap between the rolls, the straightener can be used to achieve precise straightening of the material.

The roll gap is the distance between the rolls in the straightener. By adjusting the roll gap, the straightener can be made to apply more or less pressure to the material, which can help to straighten it more effectively.

A tension device can be used to keep the material under tension as it passes through the straightener. This can help to reduce the amount of bending and twisting that can occur during the straightening process.

A laser alignment system can be used to ensure that the material is properly aligned as it passes through the straightener. This can help to reduce the amount of bending and twisting that can occur during the straightening process.

Before attempting to straighten the material, it is important to check its quality. Material that is too hard or brittle may be difficult to straighten, while material that is too soft may be prone to bending or twisting during the straightening process.

Before using the straightener, it is important to check its settings. This includes checking the roll gap, the tension device, and any other settings that may affect the straightening process.

When working with a straightener, it is important to follow proper safety precautions. This includes wearing appropriate personal protective equipment, such as gloves and eye protection, and following all manufacturer guidelines and instructions.

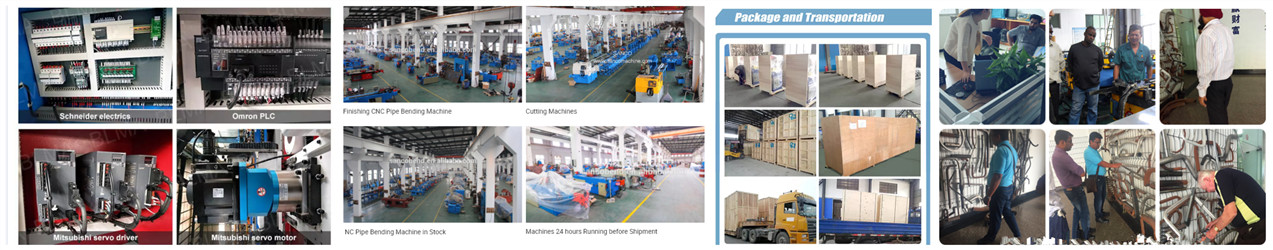

Shanghai qipang Industrial Co., Ltd. (hereinafter referred to as the “Company”) is specialized in manufacture of machining equipment for metal pipes. The Company covers an area of more than 10,000 m2 with total assets of over CNY 20 million. The main products include 9 series and over 100 models, i.e. pipe machining line, pipe cutter, pipe bender, pipe end forming machine, chamfering machine, gear grinding machine, riveting machine, arc machine and bending press.

If you want to know more about the straightener line adjustment method, please visit our website or contact us.