We are leading manufacturer in China which specialized in electrical wire straightenerand cutter supplying for over 10 years; good quality and professional service help us gain many good reputation all over the world; we hope you can join us in the future.

Besides, we are willing to offer customed service.

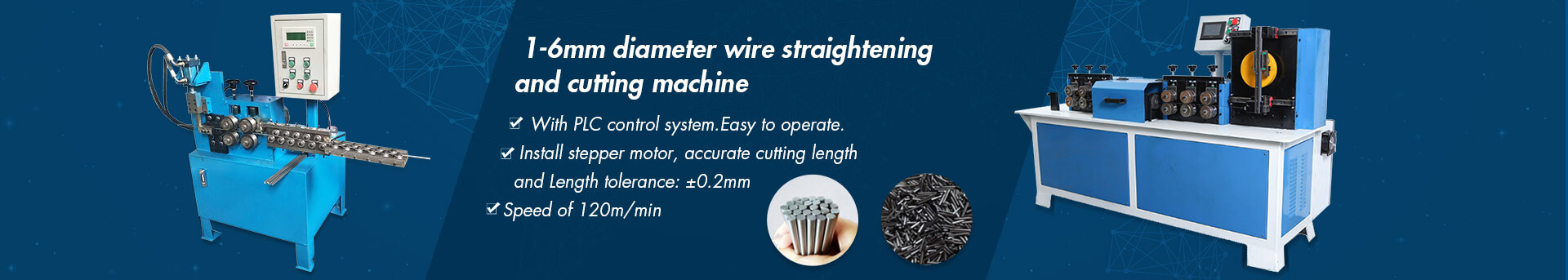

| Follow cut | 2-6MM | 3-8MM (pa hydraulic cutter) | ||||||||||

| Cutting wire diameter | 2-6mm | 3-8mm | ||||||||||

| Cutting length range | 20mm or more | 20mm or more | ||||||||||

| Wire feeding speed | adjustable speed 20-45m/min (the smaller the wire diameter, the faster the speed) | adjustable speed 20-45m/min (the smaller the wire diameter, the faster the speed) | ||||||||||

| Length error | ±0.5mm | ±0.5mm | ||||||||||

| Straightening material | ordinary carbon steel wire, stainless steel wire, copper wire, nickel-manganese galvanized wire, etc. | ordinary carbon steel wire, stainless steel wire, copper wire, nickel-manganese galvanized wire, etc. | ||||||||||

| Feeding rack | 1100*700*500 | 1100*1100*500 | ||||||||||

| Wire feeding motor | ordinary motor 1.5kw with reducer | ordinary motor 1.5kw with reducer 28 medium reducer-GH28-1500W-3S | ||||||||||

| Straightening motor | 3KW-2P | 5.5KW-2P | ||||||||||

| Follow shear servo motor | 0.75kw servo motor | 4 pa hydraulic cutter | ||||||||||

| metal straightening tools | Rail module: Taiwan | |||||||||||

| Number of wire feeding groups | 2 groups (4 pairs of wheels), outer diameter 70MM | 2 groups (4 pairs of wheels), outer diameter 70 | ||||||||||

| Control screen | touch screen | touch screen | ||||||||||

| Number of straightening blocks | 8 | 8 | ||||||||||

| Wire range | 4-10mm (ordinary carbon steel), 2-6MM, 3-8MM (pa hydraulic cutter), 4-10MM, 6-12MM | 4-10mm (ordinary carbon steel), 2-6MM, 3-8MM (pa hydraulic cutter), 4-10MM, 6-12MM | ||||||||||

| Frame size (length * width * height) | 2700*800*1500 (mm) | 2200*800*1200 (mm) | ||||||||||

| Weight | 1000kg | 1000KG | ||||||||||

| Oil pump motor | 1.5KW | 2.2 KW | ||||||||||

| Cut off the cylinder | MOB63-20 | MOB80-20 | ||||||||||

| Material receiving rack | 1.2M single slot | 1.2M single slot | ||||||||||

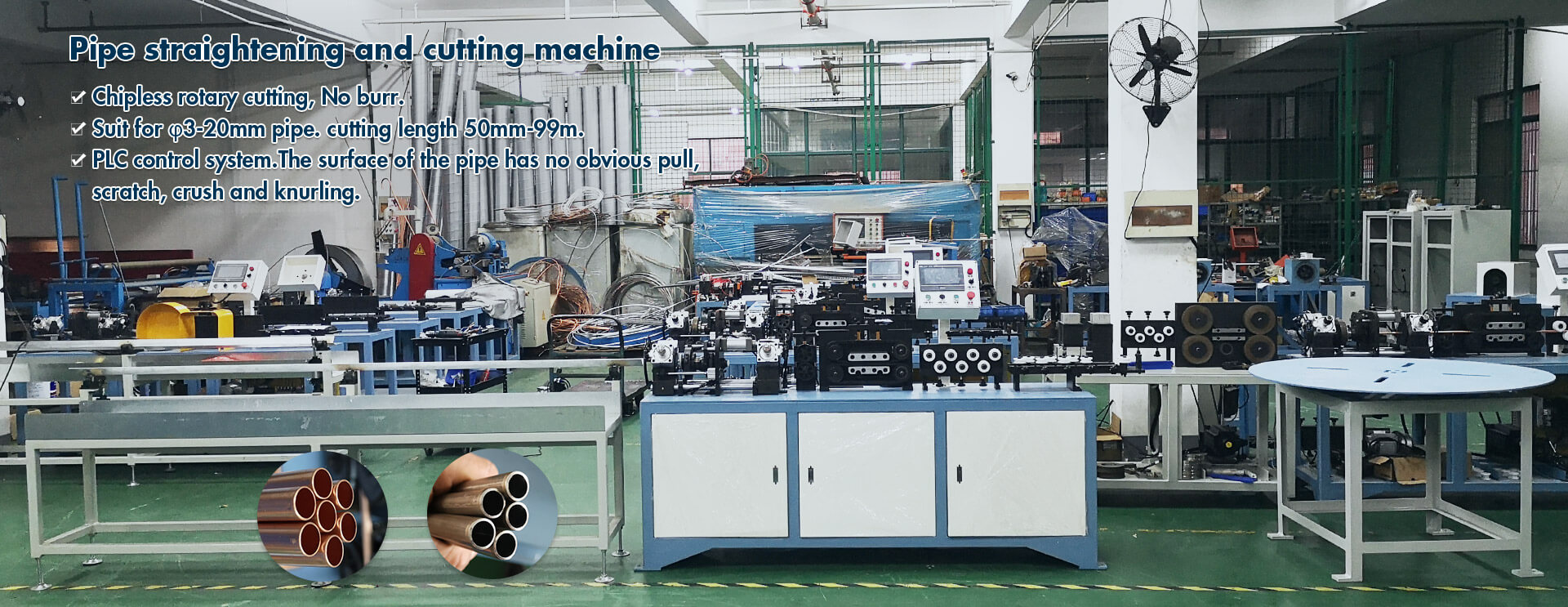

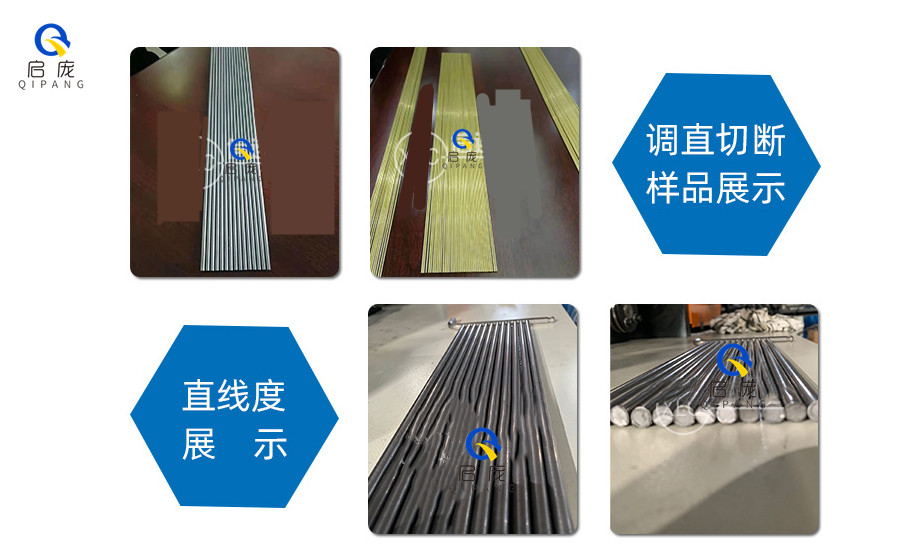

Automatic straightening machine and cutting machine exhibit:

Specifications

1. Model:2700x1500x800mm

2. Drilling crew plane height: About 850mm

3. Weight:500kg

4. Power Supply: Three-phase five-wire 380v bring zero line and ground wire

5. Power: 3kw

6. Air Pressure: 0.5-0.8mpa

7. rough shape cutting to adapt to the pipe:4-16 aluminium tube;4-16 copper pipe;4-16 band pipe

8. Feeding speed: 0-50M

9. cutting ways: Single - knife direct rotation without cuttings cutting. clipping time: 2-2.5S/time. Three meters per time about 6 seconds, An eight-hour day produces about 3,000 to 4,000 pieces.

10. Equipment use field: Automobile, air conditioning, refrigerator freezer, water dispenser, home appliance, etc.

11. control principle:PLC programmable logic controller,OP-320text operation,Synchronous belt feeding,servo motor drive,Japan omron rotary encoder counting,The pneumatic original adopts SNS.

12. This machine is aimed at the following (copper tube). The tube is straightened to the straightening mechanism of the main engine, and the servo motor drives the synchronous belt to drive the pipe to the cutting-free cutting machine.Finally, it is taken over by pneumatic aggregates, and the whole process is automatic and reliable. The machine break up and operate automatically, the mold change is simple, the operation is simple, the production efficiency is high.

13. Main structure and principle:Mechanical structure: it is composed of flat rack, straightening group, feeding tube section, cutting head section and feeding frame.

Gas path control: cylinder clamp, servo drive synchronous belt feeding tube, cylinder clamp, cutting tube, pull, cylinder connection.

Circuit control system: by PLC control servo motor forward tube, after the length of the encoder, after reaching the set length, the PLC control solenoid valve action, drive the cylinder to cut off the pipe.

Processing pipe: this equipment is a single pipe equipment, and the size of the open material pipe is applicable to the mechanical limit range. Different materials need to be replaced with straightening wheel, feeding belt, mould and central pipe.

14. Machine Features:

The precision is special, can be according to the customer's product process request and according to the purchase cost budget to make the material way, the tube is cut neatly, the rate is small or no burr, no cuttings to cut any choice.

Is simple and convenient operation, automatic control and manual control two ways, the operator easy-to-learn, smooth feeding, high degree of automation, no material and reach a preset number of cutting, automatic stop.

It is easy to maintain and maintain, use pneumatic components to control and implement parts, less lubrication points, no pollution, quick and convenient replacement of parts, and easy to keep the equipment clean.

Quick installation coil, feeding frame can use double-sided active feeding plate, can prevent materials plate caused by inertia feeding is too long, or caused by the pipe is too thin and pipe strain, so as to ensure the quality of copper pipe cutting. It can also be used for flat loading rack and easy to install copper pipe.

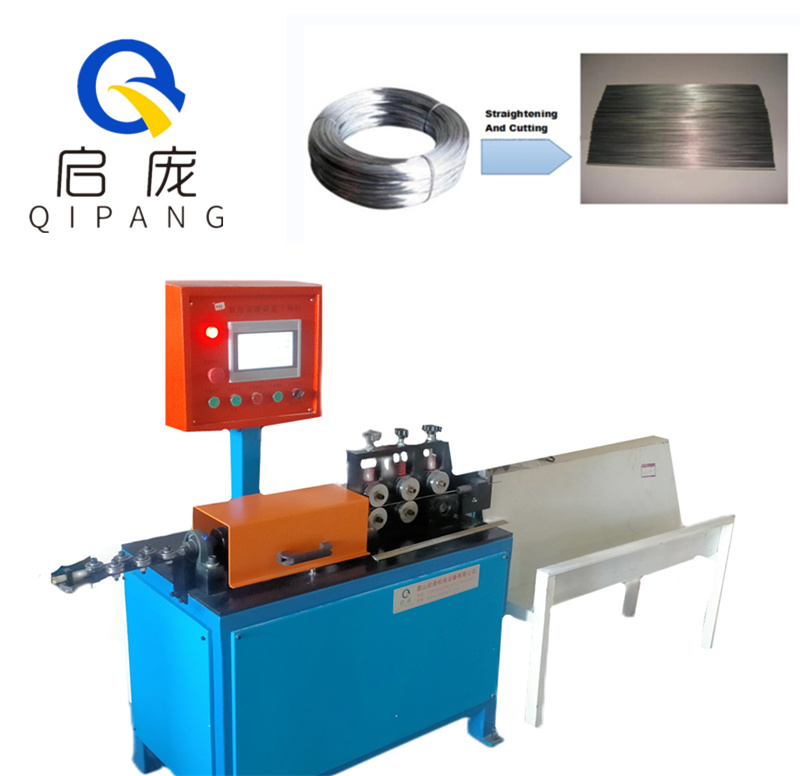

High-speed straightening and cutting machine Comprehensive factory exhibit:

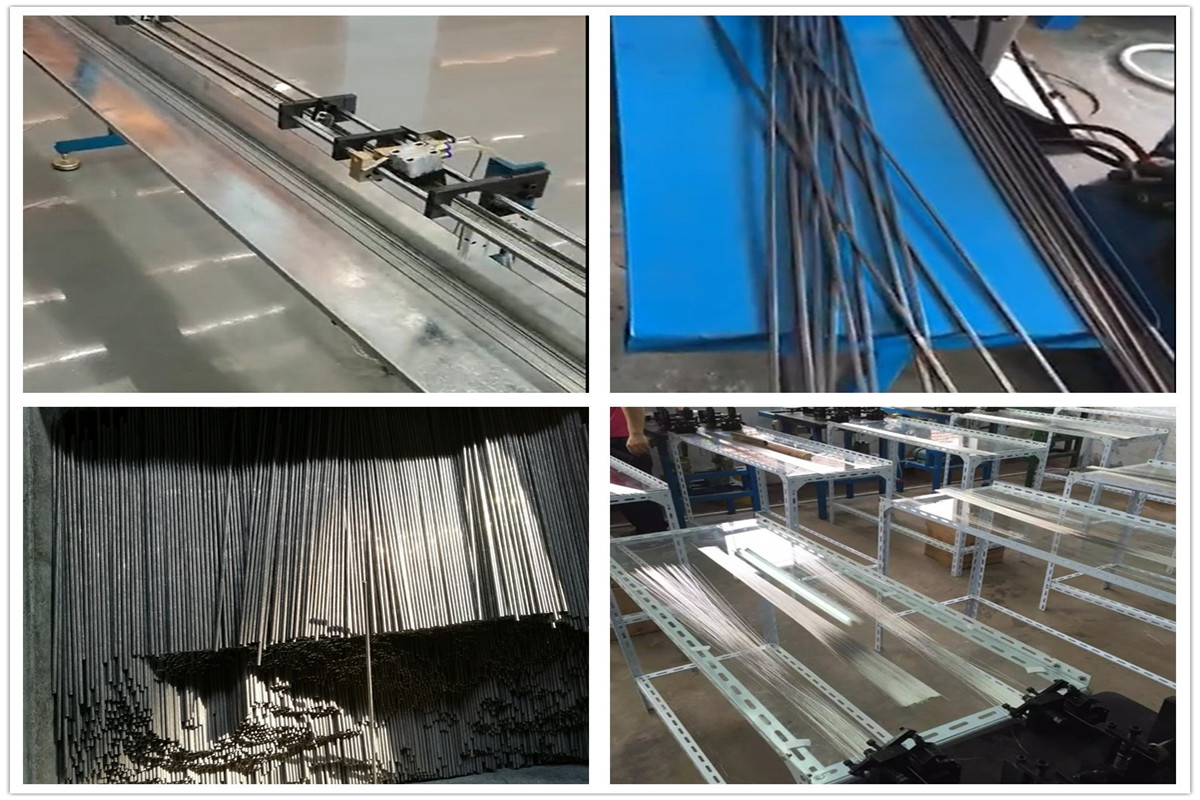

High-speed straightening and cutting machine Straightening and cutting effect exhibit:

High-speed straightening and cutting machine Product application examples exhibit:

The machine cutting wire has a wide range of applications, such as supermarket shopping carts, pet cages, handicrafts, racks, and grid baffles.

High-speed straightening and cutting machine CE & SGS Certification

We are leading manufacturer in China which specialized in products straightening and cutting machine supplying for over 10 years; good quality and professional service help us gain many good reputation all over the world; we hope you can join us in the future.

High-speed straightening and cutting machine Our company exhibit:

In addition, QIPANG is located at Zhaofeng Road Subway Station, No. 11 Jiading Anting, Shanghai.

Since 2009, the metal products series machine has been provided.

Read more:

https://www.wire-straightener.com/wire-straighteners/