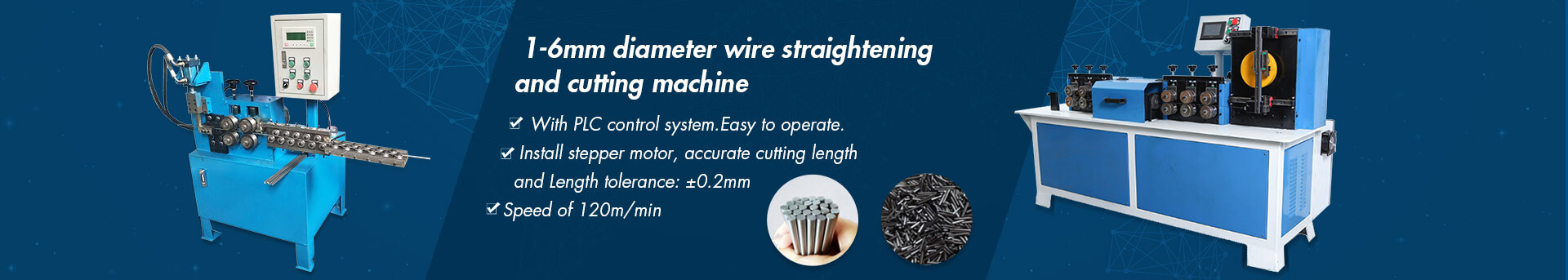

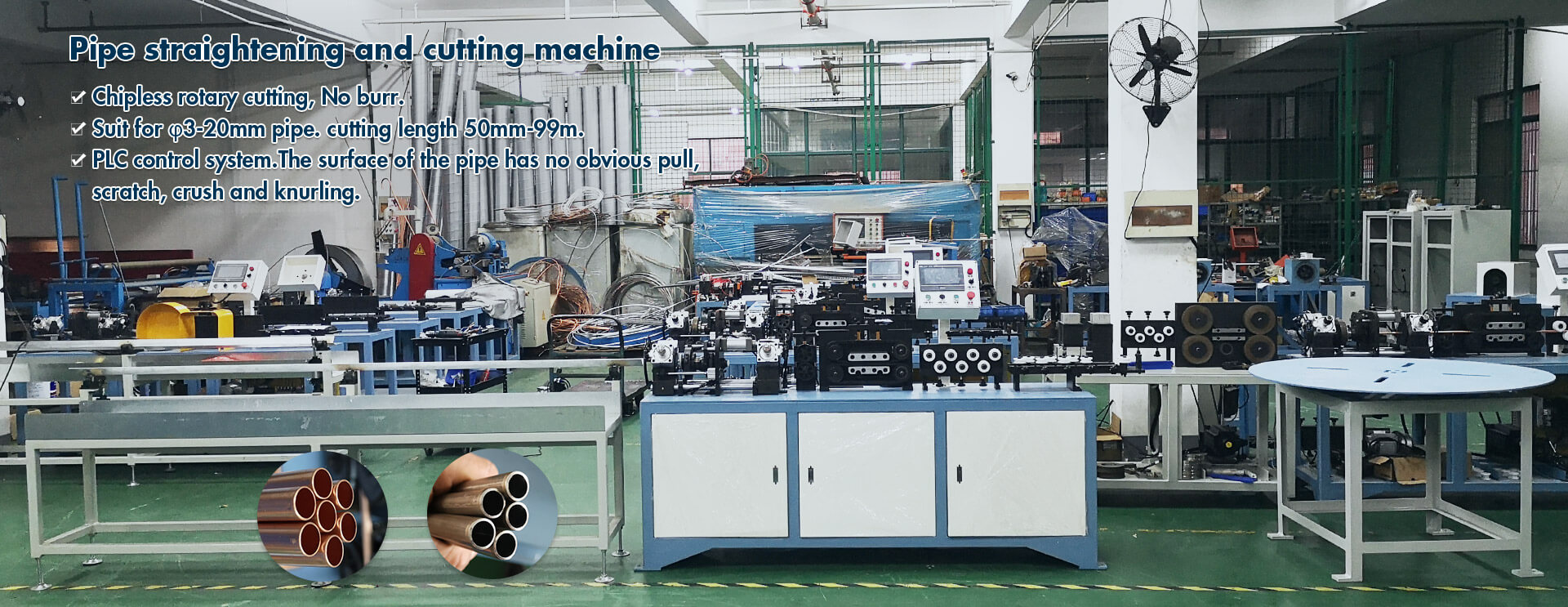

Straightening and Cutting Machine is a device for straightening and cutting metal bars, pipes, wires, etc. The straightening machine changes the straightness by extruding a bar or the like with a straightening roller. There are generally two rows of straightening rollers, varying in number. There are also two-roll straighteners, which rely on the change in the angle of the two rolls (concave in the middle, hyperbola roll) to straighten materials of different diameters. The main types are pressure straighteners, balance roll straighteners, shoe roll straighteners and so on.

1.This Wire Straightening and Cutter can be widely used in various fields of production of hardware products, handicrafts and daily necessities. Such as: bicycle basket. spokes.

2.Straightening and cutting of various metal wires such as rack, bird cage, refrigerator shelf, fan cover, construction wire, wire mesh screen, etc.

3.The production efficiency is high, and there is basically no use of personnel to look after it after normal operation.

4.The processing speed is fast, and it can be adjusted to 25-30 meters per minute.

5.The cutting length is adjustable, stepless adjustment, the standard cutting length is within two meters, and more than two meters, please contact customer service for customization.

6.High precision, the actual cutting error is less than 2mm, and the error within 1 meter of broken wire is less than 0.5mm

7.Low power consumption, only 3.75 kWh per hour.

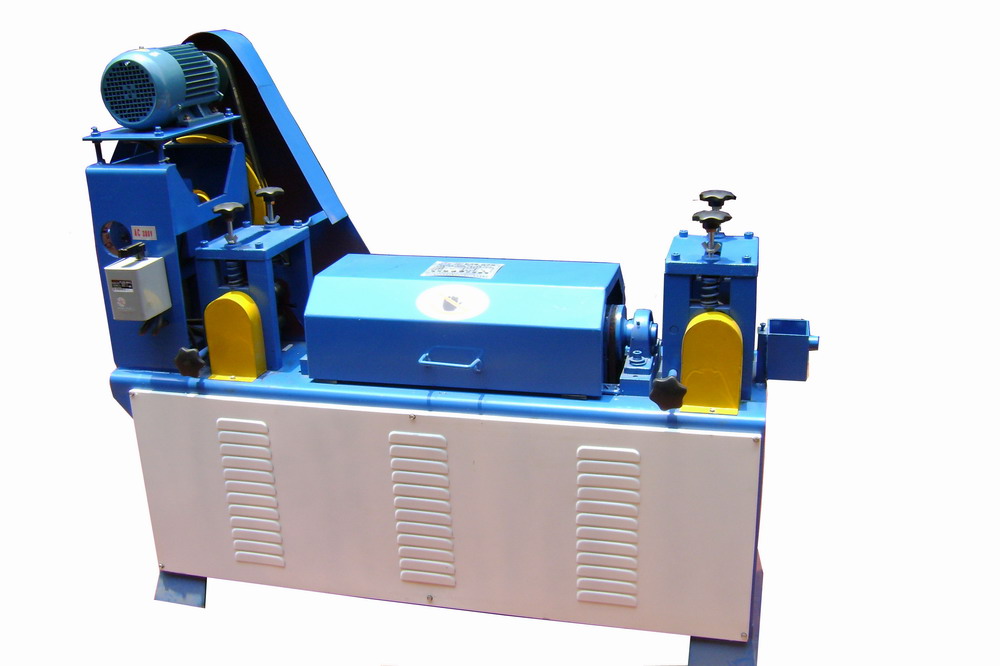

◆ Automatic Mechanical Steel Wire Straightening and Cutting Machine Principle of operation:

1.The motor speeds up through the belt drive, so that the straightening cylinder rotates at a high speed, and the steel bars passing through the straightening cylinder are straightened; the motor drives the two conveying rollers on the one hand through another pair of reduction belt transmission and gear reduction box, and pulls the steel bars forward. Movement, on the other hand, drives the crank wheel to move the hammer head up and down. When the steel bar is adjusted to the predetermined length, the hammer head hits the upper tool post to cut the steel bar. When the cut steel bar falls into the receiving rack, the tool post returns to its original position due to the action of the spring, completing a cycle.

2.The Steel Wire Straightening Cutting Machine is composed of a wire inlet part, a straightening part, a cutting part, etc. The straight line gun can automatically cut the wire at a fixed length and automatically blank the material. After loading, the machine performs automatic operation.

3.The Steel Wire Straightening Cutting Machine has reasonable structure, stable and reliable operation, simple operation and high degree of automation. The operator can manage multiple machines at the same time, which greatly improves the production efficiency. It is the equipment used by hardware, network cable and other manufacturers.

Wire straightener modle selection form:

| The number and diameter of the wire are based on the British standard wire | ||

| The relationship between British Standard Wire Gauge (BWG) number and wire diameter | ||

| Wire Diameter Number | Size | Millimater |

| 0 | 0.324 | 8.230 |

| 1 | 0.3 | 7.020 |

| 2 | 0.276 | 7.010 |

| 3 | 0.252 | 6.401 |

| 4 | 0.232 | 5.893 |

| 5 | 0.212 | 5.385 |

| 6 | 0.192 | 4.877 |

| 7 | 0.176 | 4.470 |

| 8 | 0.160 | 4.064 |

| 9 | 0.144 | 3.658 |

| 10 | 0.128 | 3.251 |

| 11 | 0.116 | 2.946 |

| 12 | 0.104 | 2.642 |

| 13 | 0. 092 | 2.337 |

| 14 | 0. 080 | 2.032 |

| 15 | 0.072 | 1.829 |

| 16 | 0.064 | 1.626 |

| 17 | 0.056 | 1.422 |

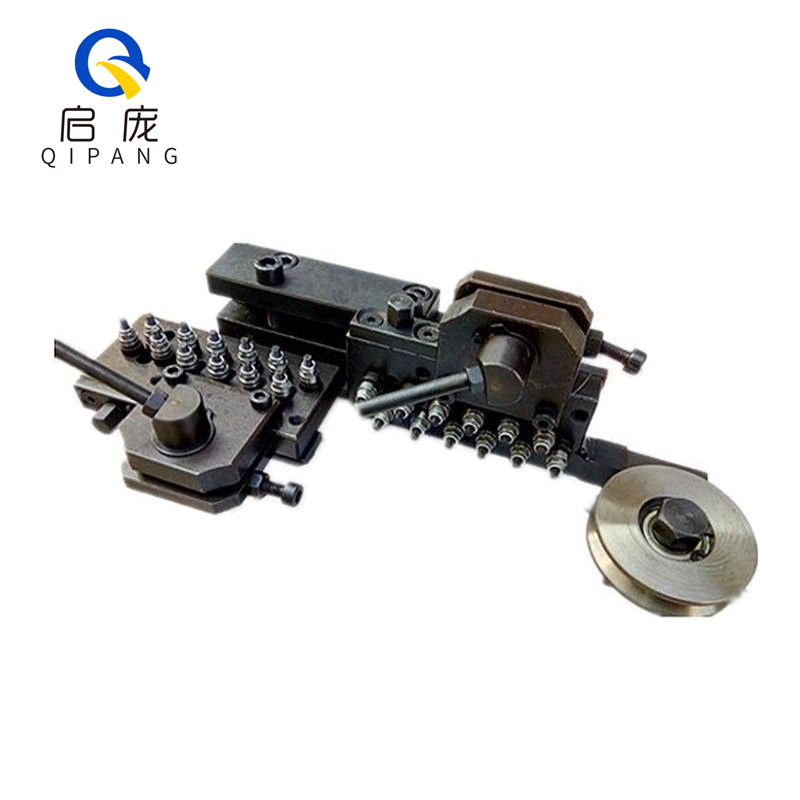

Wire Straightener series:

Steel Wire Straightening Cutting Machine type introduction:

QR series:

1. With quick opening and closing handle, the whole opening and closing, easy to enter and exit the line

2. With guide to prevent the wire from drifting

3. Light weight

PR series:

1. With bottom plate, easy to fix

2. More stable during straightening

3. High positioning accuracy

RS series:

1. Can be used for wire positioning, increase certain resistance

2. Affordable price, easy installation

3. Easy to carry

ERS series:

The center can be adjusted freely, each straightening wheel can be adjusted according to the actual situation

DRS series:

1. Each time the amount of depression is displayed, it is convenient for subsequent operations

2. High accuracy

QPR series:

1. Easy to fix with large bottom plate

2. Easy to adjust wire entry and exit with handle

3. Larger wheel spacing, better straightening effect.

Steel Wire Straightening Cutting Machine Packing:

FAQ about Automatic Mechanical Steel Wire Straightening and Cutting Machine

Q:How about your after-sale service?

A:QIPANG has a professional technology supporting team for your timely services. You can get the help you need in time by telephone, webcam, online chat (Google talk, Facebook, Skype). Please contact us once the machine has any problem. Best service will be offered.

Q: What are your payment terms?

A:100%TT or prepaid 50% , balance 50% before shipping.

Q: How can I get my order? How can I know you sent the goods?

A:We will send the goods by UPS, DHL, FedEx or sea shipment. After we sent the goods, we will give you the tracking number or other relative files for checking.

Q:What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes or wooden cartons.

Q: Will you send the installed machine or machine parts?

A:We will install the machine and test the machine before delivery. And the machine can be used directly after receiving the machine.