Hydraulic bending machine Forming Machine 2-6mm 2-7mmIron wire, stainless steel wire , bending machine for metal wire

machine equipped with stepping motor feeding, microcomputer control, make wire-feeding more accurate, with section counting, total counting function.

Specification

| TYPE 1 | |||||

| Model | 1.5-5mm | 1.5-6mm | 1-5mm | 2-6mm | 2-7mm |

| Suitable wire diameter | 1.5-5.0mm | 1.5-6.0mm | 1.0-5.0mm | 2.0-6.0mm | 2.0-7.0mm |

| Max wire feeding length | 1000mm | 1000mm | 14"(600mm) | 650mm | 1000mm |

| Motor power | 5.5KW | 5.5KW | 3.0KW | 5.5KW | 7.5KW |

| Motivation | hydrocylinder*1 | hydrocylinder*1 | stepmotor*1 | hydrocylinder*1 | hydrocylinder*1 |

| Size(L*W*H) | 2450×1100×2100mm | 2450×1100×2100mm | 2000×700×1700mm | 2450×1100×2100mm | 2450×1100×2100mm |

| Weight | 1.2ton | 1.2ton | 800kgs | 1.2ton | 1.2ton |

| Production Ability | 16Arces/Min | 16Arces/Min | 20Arces/Min | 16Arces/Min | 14Arces/Min |

| Application | This machine is suitable for the production of all kinds of steel wire, iron wire, stainless steel wire bucket handle, bucket hook, rubber bucket hook, different specifications only need to change the mold.Longer raw material can make finished product at one time | ||||

Factory Short & Packing

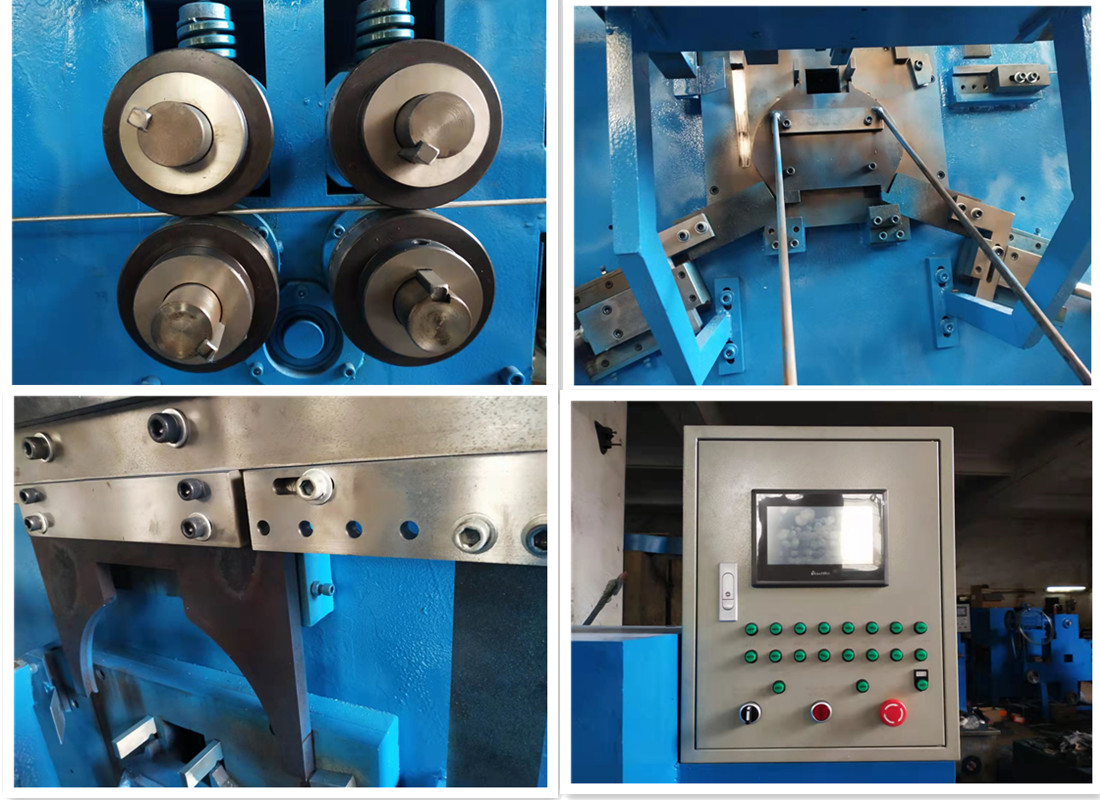

product details

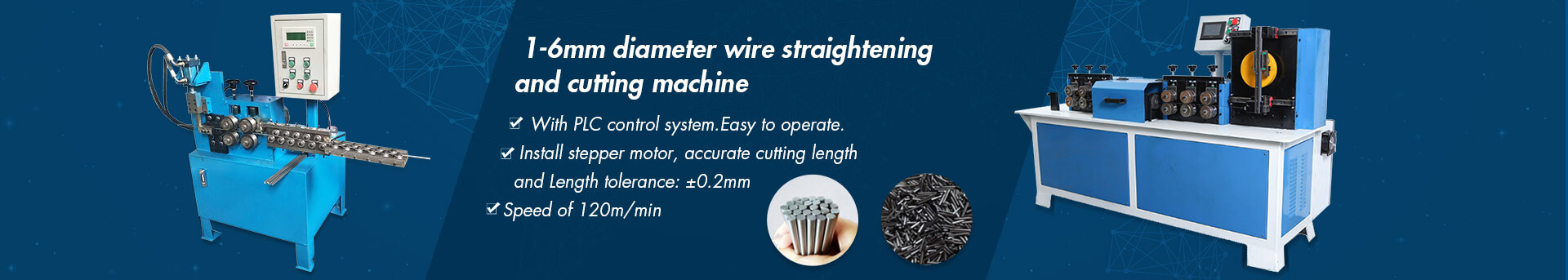

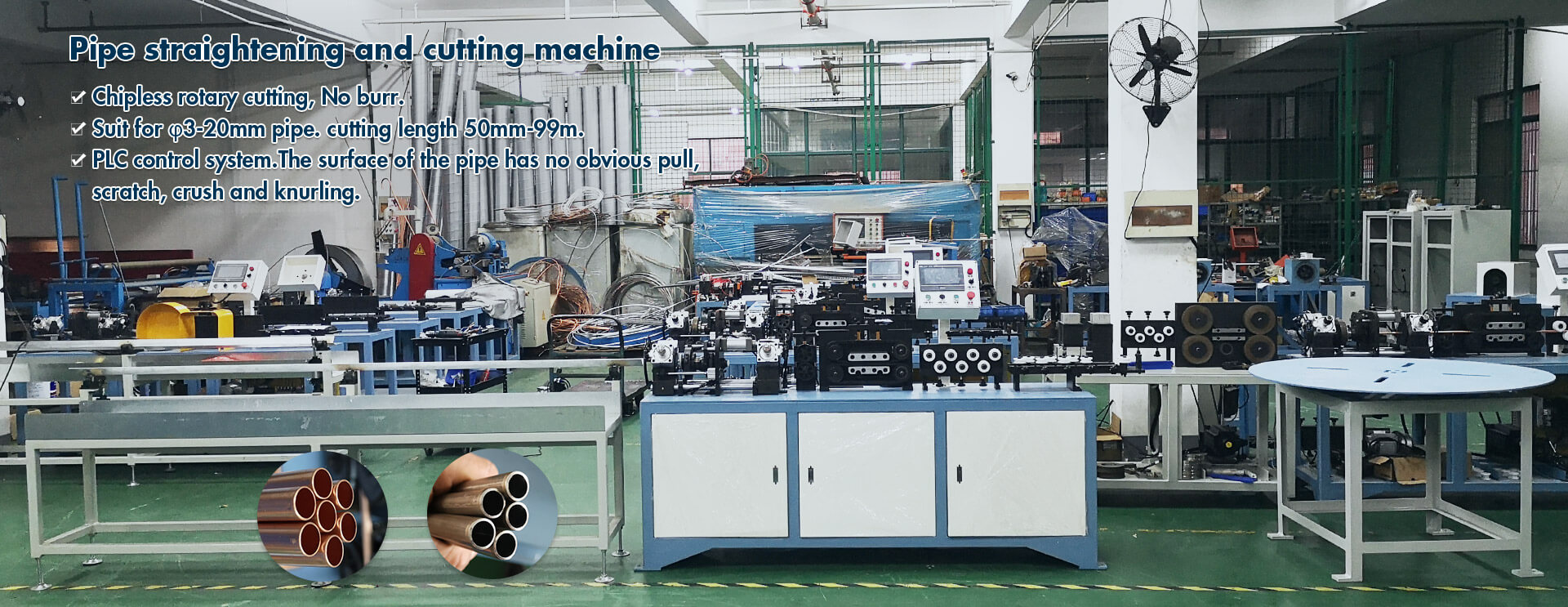

Others Products

Finished product display

Hydraulic bending machine After-sales service:

1.Maintenance period: one year

2.Training how to install the machine, training how to use the machine.

3.Engineers available to service machinery overseas.

4.Test the machine before shipment

5.Provide technical guidance relate to use the machine

6.Provide the spare parts at cost price after warranty period

7. Collect the feedback for the machine working

In addition, QIPANG is located at Zhaofeng Road Subway Station, No. 11 Jiading Anting, Shanghai.

Since 2009, the metal products series machine has been provided.

Read more:

https://www.wire-straightener.com/wire-straighteners/